Battery Passport

Commitment to Battery Passport

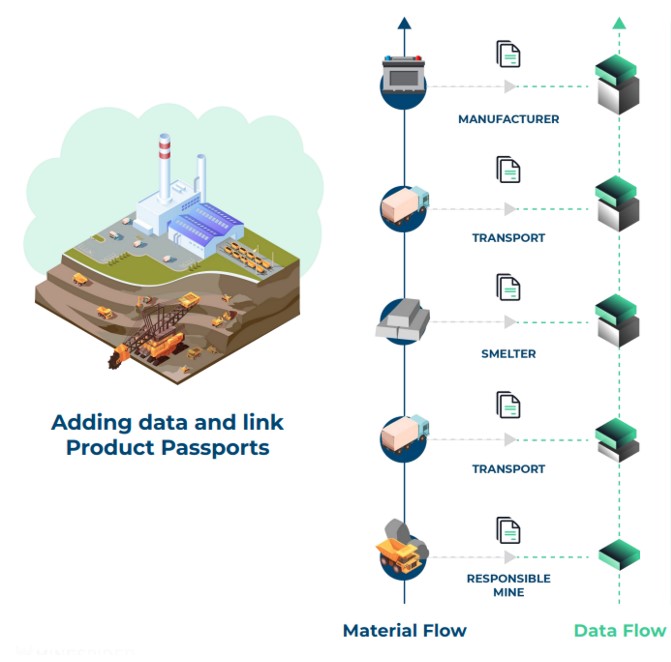

In line with DEM’s explicit ESG commitment, which is regularly validated by independent audits (DIGBEE), the issue of traceability of our commodities has been part of our DNA from the very foundation of the company. Therefore, we are constantly carefully monitoring the various providers of applications for the documentation of manufacturing data, better known as “battery passport”, and we are in close contact and exchange with them (among them Circulor, Minespider AG, Circularise etc). As soon as one of DEM’s projects for the extraction of battery metals is close to production, a digital battery passport will be issued for the respective battery metals.

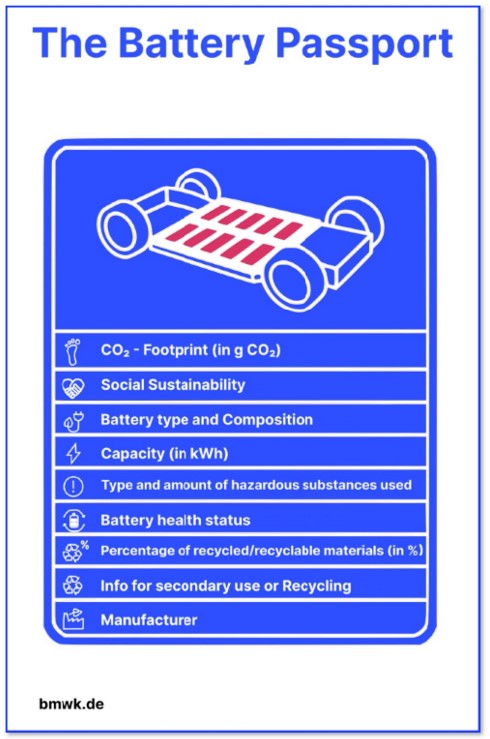

The digital battery passport is a platform providing the digital infrastructure for documentation of basic technical data related to the manufacturing and supply chains of the battery materials. This includes CO2 emissions released during production, working conditions, recyclability, etc.